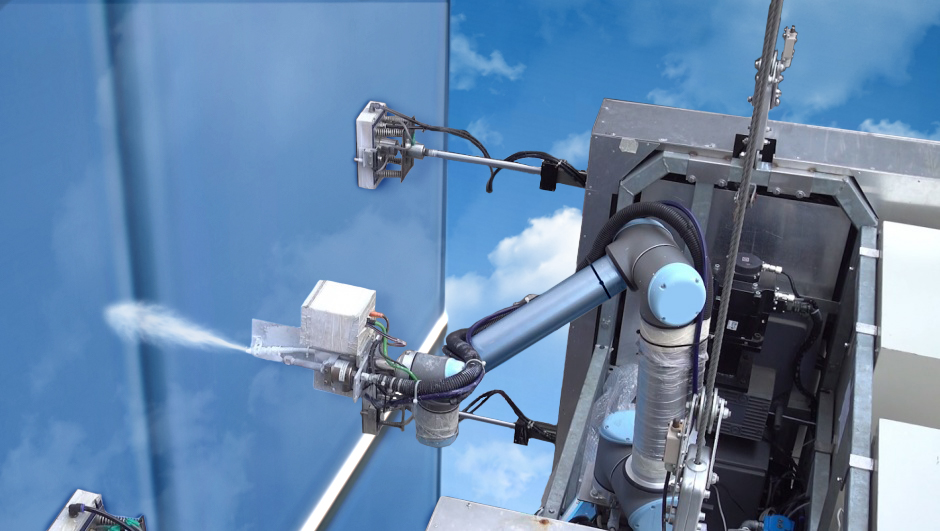

Innovative Robotic Application: Setting a New Standard

In our relentless pursuit of innovation, we have integrated cutting-edge robotics into the application process of Exicoat. Our advanced robotic systems are meticulously engineered to apply Exicoat with unparalleled precision, ensuring that every surface, whether it’s the expansive glass facade of a skyscraper or the delicate glass of a vehicle, receives consistent and uniform coverage. This robotic integration not only amplifies the performance and effectiveness of Exicoat but also redefines the standards for coating application technology..

Precision and Efficiency: The Future of Coating Application

Our state-of-the-art robotic technology guarantees a flawless finish with minimal waste, optimizing both the quantity of product used and the time required for application. Designed to handle surfaces of any scale, from towering glass buildings to intricate vehicle windows, these robots ensure that Exicoat is applied evenly across every square inch. This level of precision significantly reduces the likelihood of human error, resulting in a superior finish that enhances the longevity and protective properties of Exicoat.

Our advanced robots are engineered to apply Exicoat with unparalleled accuracy, ensuring every inch of the surface receives a flawless, even coating. This degree of precision is nearly impossible to replicate with manual application, especially on large, intricate, or irregular surfaces.

Robotic spraying significantly accelerates the application process, reducing the time required to treat even the most expansive surfaces. This leads to faster project completion, minimizing disruption and downtime for businesses.Businesses can swiftly return to normal operations, boosting both productivity and savings.

Traditional coating applications can involve risks, especially when dealing with high or difficult-to-access areas. With robotic technology, the need for scaffolding and other safety measures is reduced, as the robots can easily reach and coat these challenging areas, minimizing risk to human workers.

Robotic application minimizes material waste through precise and accurate spraying, ensuring that only the necessary amount of Exicoat is used. This efficiency not only maximizes resource utilization but also reduces overall costs, making the application process more economical.

The use of robots in the spraying process optimizes precision, significantly reducing overspray and minimizing waste. This enhances the environmental sustainability of Exicoat's application, aligning with our commitment to eco-friendliness by ensuring that every aspect of the process is as environmentally responsible as possible.

Exicoat not only enhances energy efficiency but also helps protect glass surfaces from environmental wear and tear. By preventing UV and IR damage, it can extend the lifespan of windows and vehicle glass, reducing the need for frequent replacements and contributing to long-term savings.

The integration of robotics into Exicoat’s application process represents a leap forward in coating technology. By combining the unmatched durability and protective qualities of Exicoat with the precision and efficiency of robotics, we are able to offer a solution that not only meets but exceeds industry standards. Whether protecting the glass of vehicles or the windows of high-rise buildings, our robotic application process ensures that Exicoat delivers optimal performance and long-lasting results.

Consistent Quality: Robotic application ensures a level of consistency that is virtually impossible to achieve through manual methods. Each pass of the robot delivers an even coat, eliminating streaks, bubbles, or uneven thicknesses that can occur with traditional application techniques.

Time-Saving Efficiency : By automating the application process, robotic systems drastically reduce the time required to complete large-scale projects. This means faster project turnaround times and reduced downtime, allowing for quicker occupancy or use of treated spaces.

Environmental Responsibility: The precision of robotic spraying minimizes overspray and reduces waste, aligning with our commitment to sustainability. By using only the necessary amount of Exicoat, the environmental impact is minimized, making the process both eco-friendly and cost-effective.

Safety and Accessibility: Robots can easily access high or hard-to-reach areas, reducing the need for scaffolding or ladders and thereby enhancing safety. This is particularly beneficial for coating large buildings, where manual application would require extensive safety measures.

Customizable Application : Our robotic systems are equipped with sophisticated sensors and software that adapt to the unique contours and textures of any surface. This adaptability ensures that Exicoat is applied in the most effective manner possible, regardless of the complexity of the surface.